The Ultimate Guide To Glazed Spandrel Panel

Table of ContentsWhat Does Glazed Wall Panels Do?Facts About Glazed Panel Window RevealedThe Buzz on Glazed Window Panels

The life span span of elements that are mated with the drape wall into an assembly must match the life span span of the drape wall itself. Need long lasting flashing materials, non-corroding attachment hardware and fasteners, and moisture resistant products in regions subject to moistening. Laboratory testing: For tasks with a significant amount of custom-made curtain wall, require lab screening of a mock-up curtain wall prior to completing task shop drawings.

Define that lab tests are to be performed at an AAMA Accredited Laboratory center. Field Mock-up: For all curtain walls, stock or custom, need building and testing of a field mock-up agent of the wall/window assembly. This is best arranged prior to the release of store illustrations for window production, so that there is an opportunity to make design changes based upon the test efficiency of the field mock-up.

Field screening of curtain walls: Need the field screening of drape walls for air infiltration and water penetration resistance, for quality assurance of curtain wall fabrication and installation. Need several tests with the first test on initial setups and later tests at approximately 35%, 70% and at final conclusion to catch problems early and to validate continued workmanship quality - glazed wall panels.

Shop drawing coordination: Need drape wall setup shop drawings revealing all surrounding building and associated work, consisting of flashings, accessories, interior finishes, and indicating sequencing of the work. Curtain wall systems, particularly unitized systems, need competence on the part of the building designer, the producer, the producer, and the installer. For all however the most basic of systems, the designer needs to think about engaging an outside consultant, if such know-how is not offered on the personnel.

Getting The Glazed Panel Window To Work

The information related to this area of the BEDG on the WBDG were established by committee and are meant exclusively as a means to highlight basic design and construction principles only. Suitable use and application of the concepts illustrated in these information will differ based upon performance considerations and environmental conditions special to each project and, therefore, do not represent the final opinion or recommendation of the author of each area or the committee members responsible for the advancement of the WBDG.

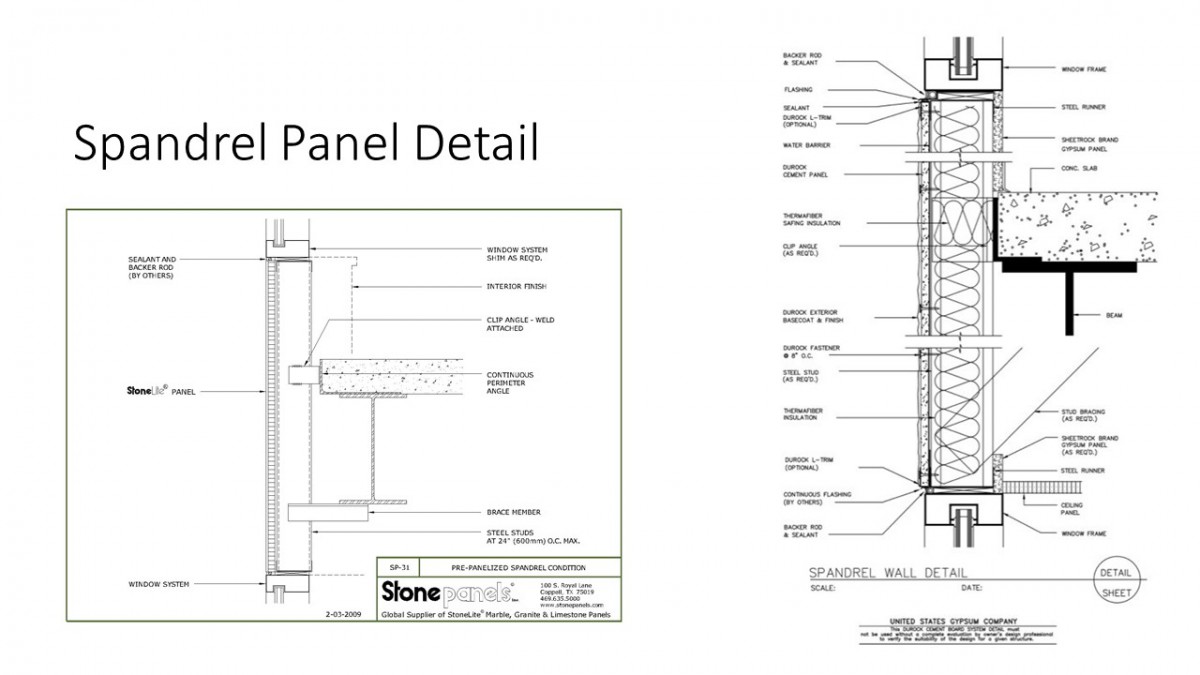

Elevation includes splice joints to accommodate thermal motion of the curtain wall frame. A through-wall metal flashing at the base of the brick cladding above the drape wall protects the curtain wall from leak through the wall above (see Exterior Wall) for combination of the these parts. Locate exterior boundary sealant joints behind trim cover to prevent water inside trim cover from bypassing the exterior sealant joint.

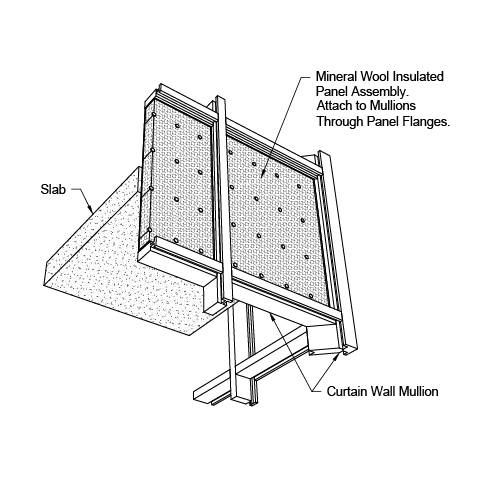

Find setting blocks regarding not obstruct water drainage from the glazing pocket. Offer anti-walk blocks at the jambs of the glazing systems. Blocks should be gapped 1/8-inch from the edge of the glazing system. Keep in mind: the following U-series details are thanks to The Facade Group This elevation reveals a common unitized drape wall assembly hung from the edge of the floor slab.

How Glazing Infill Panels can Save You Time, Stress, and Money.

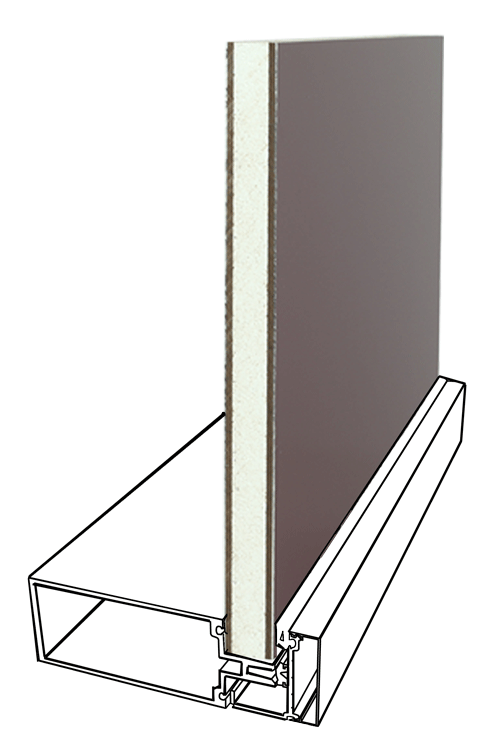

Spandrel glass adapters are used to decrease the depth of the glazing pocket to accommodate minimized profile of spandrel glass. Spandrel glass adapters ought to be fully bedded in sealant and incorporated with glazing pocket glazed window panels corner seals to prevent water leak from glazing pocket to building interior. Unit measurement of mating head and sill extruded profiles enables specified floor to flooring deflection at the stack joint.